-

PARAMETERS AND PERFORMANCE

PARAMETERS AND PERFORMANCE

● Weighing range: 18t to 100t.

● Weighing method: Two-way automatic bogie dynamic weighing.

● Weighing speed : 3 ~ 15km / H.

● Maximum vehicle speed: 40km / H.

● Weighing accuracy: It is better than the required in the the national standard JJG234-2012"Automatic Rail-weighbridges" verification regulation tolerance provisions requirements.

● Print display items: date, model, car number, unit name, arrival, gross weight, tare weight, net weight, profit and loss, etc. ( can also be adjusted according to user needs )

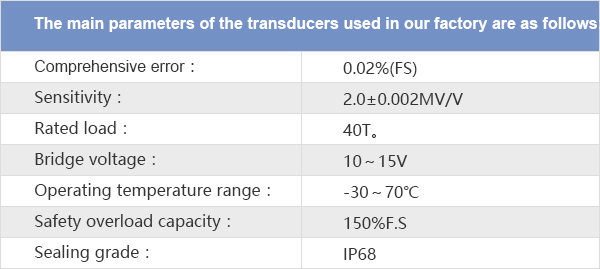

● Transducer: Four high-precision resistance strain gauge load cells . The rated load of each transducer is determined according to the size of the weighing range.

● Effective length of weighing rail: 38 00mm (special requirements can be specially designed).

● Inner gauge: 1435 mm (special requirements can be specially designed).

● Power consumption: The power consumption of this machine is not more than 500W.

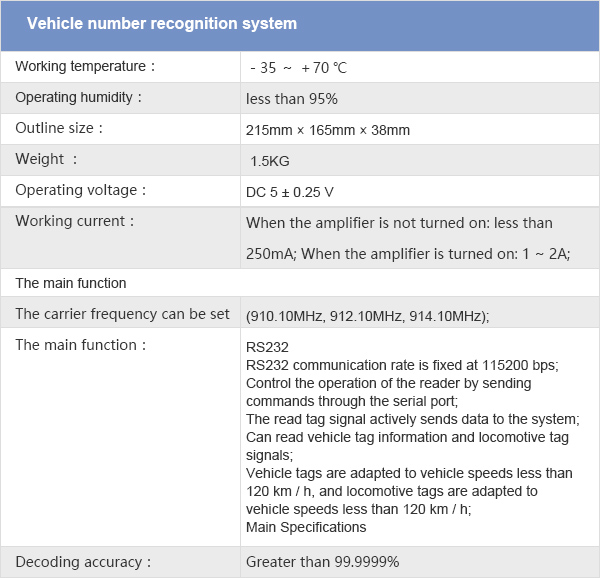

● Automatic car number identification system: It can automatically read relevant information such as car number and tare weight of railway wagons.

● Operation mode: unattended, local duty operation during measurement, and provides functions such as network data query with upper computer.

-

WORKING CONDITIONS

WORKING CONDITIONS

● The weighed vehicle shall meet the requirements of railway operation, a four-axle freight train with a weight saving less than the nominal weight and an internal gauge of the standard series gauge.

● The two sections of the weighing platform should each have a straight track segment of not less than 80 meters , including a 25- meter monolithic concrete track bed.

● The train is required to pass the weighing platform smoothly during weighing , and it is not allowed to accelerate or brake suddenly during the weighing process.

● The weighing control room is required to be sealed and dustproof. The room temperature should be controlled within 10 ℃ ~ 30 ℃ , and the relative humidity should be less than 95% . The location and conditions of the weighing house should meet the relevant requirements specified in the national standard "Electronic dynamic rail-weighbridge".

● The weighing control room should be equipped with an AC power supply , a two-phase three-wire power supply with a voltage of 220V , the voltage error is less than ± 10%, the frequency is 50Hz , the error is less than ± 2% , and the waveform distortion rate is less than 5% . The ground resistance is less than 4 ohms.

● There should be an independent and good grounding device near the mechanical weighing platform, and the grounding resistance should be less than 4 ohms in the driest season.

● For the device to work , around the equipment should avoid interfering with strong electromagnetic fields , avoid corrosion corrosive substances on the device.

● It is strictly forbidden to engage in electric welding operations near the equipment, nor is it allowed to use steel rails and equipment for conductive lines.

-

TECHNICAL DESCRIPTION

TECHNICAL DESCRIPTION

Electronic dynamic rail-weighbridge is an automatic measuring equipment for dynamically weighing on-the-fly load trains. It consists of a mechanical weighing platform , a high-precision resistance strain gauge load cell, a data acquisition channel, and a microcomputer control system. Auxiliary parts such as the foundation track bed specially designed and constructed are also matched with it.

When a certain speed train (. 3 ~ 18km / H) steady speed by weighing table, the table put a transducer in the weighing signal into the train weight is millivolt voltage signal proportional thereto , the transducer output voltage signal , the amplified channel data acquisition, filtering, analog / post-digital conversion processing, into the computer via an interface , a computer data signal by taking the arithmetic processing data , calculate the weight of each section and the speed of the vehicle , a monitor and printer and , In the order of weighing , displayed and printed in the form of Chinese characters.